ABOUT US

Welcome to Tridus! Since 1982, Tridus has dedicated itself to the development, manufacture and marketing of rare earth permanent magnets. During the past 35 years, Tridus has been leading the development of the North American rare earth permanent magnet industry. Our magnets are used in a myriad of applications ranging from branded high end audio transducers to current model year electric vehicles. Tridus is committed to serving its customers with high quality products and services.

HISTORY

Tridus was incorporated in 1982 (Los Angeles, CA) and quickly established a joint venture with San Huan High-Tech., Inc to manufacture sintered NdFeB magnets in Ningbo China. In 1993 our joint venture signed patent license agreements, authorizing us the manufacture and sell sintered NdFeB magnets. Our joint venture was the exclusive Chinese licensee for more than 7 years. Today, we are a leading supplier of rare earth permanent magnets and our group holdings are publically traded on the Shenzhen stock exchange.

DELIVERING WITH TRIDUS

- Pioneer in the development of the Rare Earth Permanent Magnet Industry

- Hundreds of millions of magnets shipped

- Continuous Improvement Culture

- Excellent Track Record

- Local Application Engineering Support

- Local Rapid Prototyping

- Global Production

- Close to raw material

- Supporting our customers with Intereset and Dedication

- Collaborating from Design to Production

- Focus on Long-Term Customer Partnerships

- Delighting Customers

INDUSTRIES

AUTOMOTIVE

There are many permanent magnet applications in a typical automobile such as PMDC motors utilized on power windows, seats, mirrors, windshield wipers, and cooling fans to name a few. There are countless sensors ranging from proximity sensors to Hall Effect sensors used in a vehicle. In addition, permanent magnets are used in generators in Electric Vehicles, Hybrid EVs, and EREV as well as electric pumps, starters, electric valve actuators, electric power steering (EPS) and speakers. Tridus supplies permanent magnets to various applications in the automotive industries.

CAPABILITIES

Our engineering team is critical to the service we provide to our customers. Tridus is here in California to provide the customer with proper magnetic material selection, design to ensure cost effectiveness, vast coating selections, and assembly designs. Furthermore, Tridus offers full factory support direct from China.

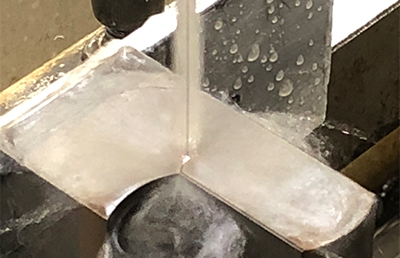

Our dedicated manufacturing team prides itself on fast turn-around prototypes, and when coupled with our outside vendors, we’re able to provide customers with industry-leading timelines.

Our China manufacturing joint venture represents our core capability of supplying world-class value through product quality by focusing on lean manufacturing models and enabling cutting-edge powder metallurgy and assembly technologies. Our technology and magnet solutions result in millions of magnets shipped globally. We boast the fact that we manufacture one of the highest quality and have the largest manufacturing facility in the world.

Magnet stabilization is achieved by saturating the magnet and then exposing the magnet to thermal or magnetic stress. Magnet calibration is achieved in much the same way, but the goal of the calibration process is to tighten the magnetic performance tolerance. Tridus engineers are capable of designing a stabilization or calibration process for the demanding magnetic application. Tridus has numerous tools & accessories for various testing methods to ensure customer’s requirements.

Tridus has one of the most extensive in-house magnetic measurement laboratories on the West Coast, we can measure with high accuracy using the following equipment:

- BH Curves @ RT and up to 200C

- Flux density

- Total Flux

- Humidity Chamber Aging Test

- Highly Accelerated Stress Test

- Oven Chamber